Phone : +91-9827113763 | +91-7587733050

INPUT SIZE: 0-3 mm

PRODUCTION CAPACITY: UP TO 300 t/h

Quick Overview

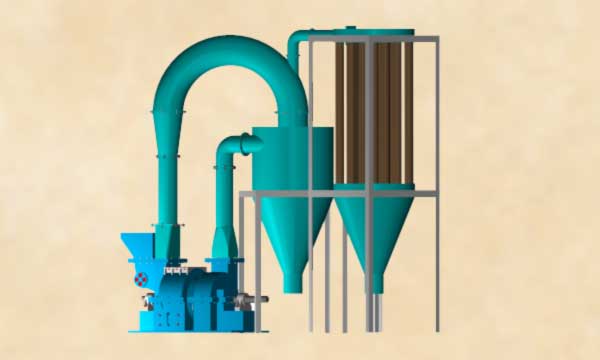

We are An ISO-9001:2015 Certified Company call: +91-9827113763 for wide range of Impact Pulverizer Manufacturers in Delhi India. The Impact Pulverizer is a versatile grinding unit of heavy construction and we areImpact Pulverizer Manufacturers in Delhi India. The unit is especially designed for the medium fine, and fine size reduction. The Pulverisers meet most capacity requirements and lend themselves to a wide degree of adjustments with fineness of the finished product ranging from about 60 mesh to bulk passing through 325 mesh, depending on a considerable extent to the particular material being handled. Unlike an ordinary hammer mill, it has no screens to break, wear out or clog in the crushing chamber. The Impact Pulverizers combines grinding, classifying and conveying all in one single unit.

Working Principle

The Impact Pulveriser consists of an encased rotor carrying swing hammers, whizzer classifier for fineness regulation, and Blower Fan mounted on a solid shaft. Raw material to be pulverised enters the crushing chamber through the hopper and automatic rotary feeder. The impact of the hammer on the feed material against the Liner plates reduces it into fine powder. The ground material is carried towards the whizzer classifier for classification and the over size particles are rejected by the classifier and returns to the crushing chamber for further grinding. The classified material is then conveyed into the cyclone for collection and bagging. A dust collector is provided in the system for ensuring dust Free operation and no loss of ground powder.

Apllication

The Impact Pulverizers are used for a wide range of application e.g. Agricultural Chemicals, Carbon & Graphite, Coal, Coke, Coconut Shell & Wood Saw Dust, Clay, Dye Stuff & Pigments, Detergents, Ferro Alloys Fertilizers, Fillers, Food Products, Herbs & Spices, Insecticides and Pesticides, Katha, Marine feeds, Minerals, Plastics, Pharmaceuticals, Resins, etc.

Features:

- Easy starting;

- Cold & silent running;

- Dust free operations;

- Robust Construction

- Low Specific Power Consumption

- Durable Long Life

- Guaranteed Grinding Efficiency

Pulverizer Used To Process Following Materials

- Aluminium Dross

- Limestone

- Glasse

- Coal and Lignite

- Clay

- Sand

- Phosphate

- Coke

- Silica

- Bauxite

- Dolomite

- Grain

- Barytes

| Chamber Diameter | ********* (mm) |

| Speed | *******(RPM) |

| Capacity | ******* (T/H) |

| Power (kW) | ******* Power (kW) |